Blog

Automated Sheet Metal Fabrication and Robotics Are The Future

What is Automated Sheet Metal Fabrication? When automation and robots work with humans, it’s possible to speed up production times, create greater manufacturing precision, and provide high-quality products more consistently.

Here's how it works...

Less Fatigue, Fewer Mistakes

Traditional custom mechanical workflows require people to manually load sheet metal onto a turret or laser to create blanks (think of it like a cookie cutter). From there, the part is moved to the press brake department for bending, where another person manually operates the brake and manipulates the metal into the desired shape. It then moves on to assembly, where yet another person (or many people) put the pieces together.

These are labor-intensive, time-consuming processes that require manual setups to achieve each step.

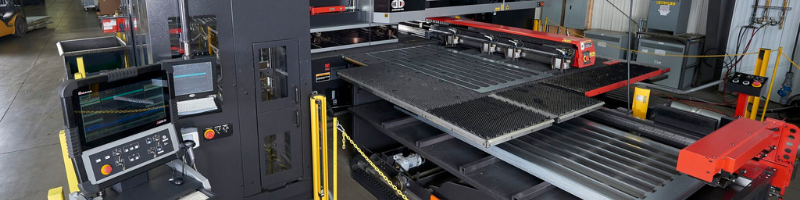

Automation and robots, however, can speed up and simplify these processes. First, they punch or cut the sheet metal using an automated turret/laser combo with an automated loader/unloader. From there, the part is moved to a robotic brake or panel bender where all tool changes happen automatically and bends are made faster and more precisely. By the way, all of this requires fewer people to monitor multiple machines.

After bending, the more complicated, repetitive, or ergonomically stressful assembly functions can be handled by a robot. That robot then hands the part off to a person or assembly line for final assembly and packaging.

When this process is automated and robots move the parts in and out of machines, there is zero fatigue, meaning there are fewer mistakes.

All of this has positive implications for costs. Because production can continue with less supervision, production times can be sped up since robots work around the clock, helping you meet tight deadlines and produce more parts faster.

The Benefits of Automation

Flexibility

Sheet metal automation allows for quick changeovers between part numbers — something that is particularly helpful depending on your mix of products. Machines with automatic tool changeovers cut set-up times to almost 0, a process that can takes hours depending on part complexity

Additionally, engineering changes are quicker because you only have to update the program on the machine that’s being affected by the change.

Scalability

Automation and robotics allow sheet metal forming manufacturers to scale up or down depending on your current demand. With the right automation and robotics in the mix, you can quickly scale your production programs without increasing labor, helping you go from prototype to production quickly.

Speed

Production speed can be improved with automation. Automatic loaders and unloaders can continuously feed a machine without a person having to manually load and remove large pieces of sheet metal. Collaborative robots (cobots) can be used for press tending, pick-and-place operations, and assembly to quickly and efficiently complete repetitive functions without any downtime.

Technical Expertise

While automation offers all the above benefits, in-house technical expertise to develop robotic operations is just as important. In-house experts with acute robotics knowledge are better able to support customers through the DF(x) process.

This expertise allows engineers to consider the most efficient way to produce specific sheet metal products and parts. Because they have all the resources and expertise of working with specific types of equipment, just one small decision can change the entire program a robot is running, saving time and costs.

Other Benefits

Sheet metal automation and robotics have plenty of other benefits, as well.

They reduce waste (scrap), provide higher quality products, increase capacity and produce high-volume output, create more consistent cycle times (the time it takes to produce one part), reduce lead times, reduce touchpoints on individual parts, refine form accuracy, and improve ergonomics and safety for employees.

In the end, engineers and operators work in tandem with automation and sheet metal robots in sheet metal manufacturing to create repeatable and predictable processes and parts.

For more information about automation and robots, check this out.

Recent Insights

News

Blog

White Papers