Blog

The New Dawn of North American Manufacturing

The manufacturing industry in North America is making a comeback, driven by strong incentives, consumer demand, and impatience with the global supply chain.

June 6, 2023

Why Should I Choose a North American Manufacturing Partner?

North American manufacturers have laid the groundwork for a resurgence. With local economic incentives, improved manufacturing technology, and companies welcoming eager workers with open arms, American manufacturing is poised to stand tall once again.

The manufacturing industry is in recovery after the COVID-19 pandemic stalled the global supply chain. This comes after 40 years of shifting manufacturing processes and supply chain management overseas, particularly to China. The idea of faster production at a lower cost pulled companies towards partnerships in Asia and the Pacific region. However, North American manufacturing was already on the rebound in the decade before the pandemic. Now, there is extra incentive for American companies to partner with contract manufacturers and precision manufacturing companies at home.

Recent U.S. legislation gives manufacturing companies further motivation to design, build, and deliver in North America. As part of the Inflation Reduction Act, a landmark law aimed to curb inflation and invest in domestic energy production, facilities can qualify for tax credits by sourcing iron, steel, and manufactured products from the United States. The 2022 bipartisan CHIPS and Science Act was designed to boost domestic high-tech research and manufacturing of semiconductors, primarily to counteract China. The law has a far-reaching impact on the American manufacturing industry by providing funds and incentives to create manufacturing jobs, enhance supply chains, and advance U.S. global leadership in the technologies of the future. Additionally, the Bipartisan Infrastructure Law includes federal funding for transportation programs, broadband access, clean water, and electric grid renewal… providing ample opportunities for North American contract manufacturers.

North American Economic Boost

There is increasing demand for skilled workers in the manufacturing industry, and communities across North America can benefit. According to the U.S. Bureau of Labor Statistics, there are nearly 13 million people employed in the manufacturing industry in the U.S. The industry was already starting to encourage more workers to join its force before the pandemic. According to the McKinsey Global Institute (MGI), 1.3 million manufacturing jobs were added to the economy between 2010 and 2019. Analysts suggest continued growth could boost the U.S. gross domestic product (GDP) by more than 15 percent over the rest of the current decade.

Consumers seek out companies that utilize local resources and create jobs in their communities. Seeing “Made in America” stamped on a product lets consumers know their purchase puts money into local pockets. That leads to higher profits for companies who partner with North American contract manufacturers.

Speed to Market

Many innovative companies, such as those in the Information and Communications Technology (ICT) sector, have fast design cycles and need to scale into production quickly. Having a manufacturing partner in the same region and time zone makes it easy for designers, workers, and engineers to collaborate or work together on site. It’s crucial for engineers to have exceptional relationships with their manufacturing partners so they can communicate product revisions and move quickly into production.

Having the ability to scale into production quickly is an enormous benefit of having a manufacturing partner in the same region. There are also numerous cost advantages to manufacturing and delivering within the same region, including reduced shipping costs. Cadrex is the largest mechanical solutions provider in North America, and we can tap into our vast network while providing regional supply chain support. In addition to locations throughout the U.S., we have a manufacturing facility in Monterrey, Mexico, allowing us to deliver high-quality fabricated sheet metal parts, stamped parts, machined components, injection molded parts, mechanical assemblies, and full integrations throughout North America. Our footprint in the U.S. and Mexico is strategically positioned with mirrored capabilities between sites.

Supply chain management is easier and more cost-effective when a product is manufactured within the same region of its end market. Shipping delays and blockades are less likely when the physical distance and communication gaps are smaller.

Environmental Benefits

Keeping the supply chain within one region reduces emissions by being closer to the end use point. Simply put, less travel for shipping and delivery means less impact on the environment. This often adds to a company’s sustainability efforts. For example, Cadrex offers custom packaging solutions for programs to cut down on crates, pallets, and single-use items. It’s also easier for American companies to understand and comply with environmental regulations in North America as opposed to trying to navigate environmental rules in Asian and Pacific countries.

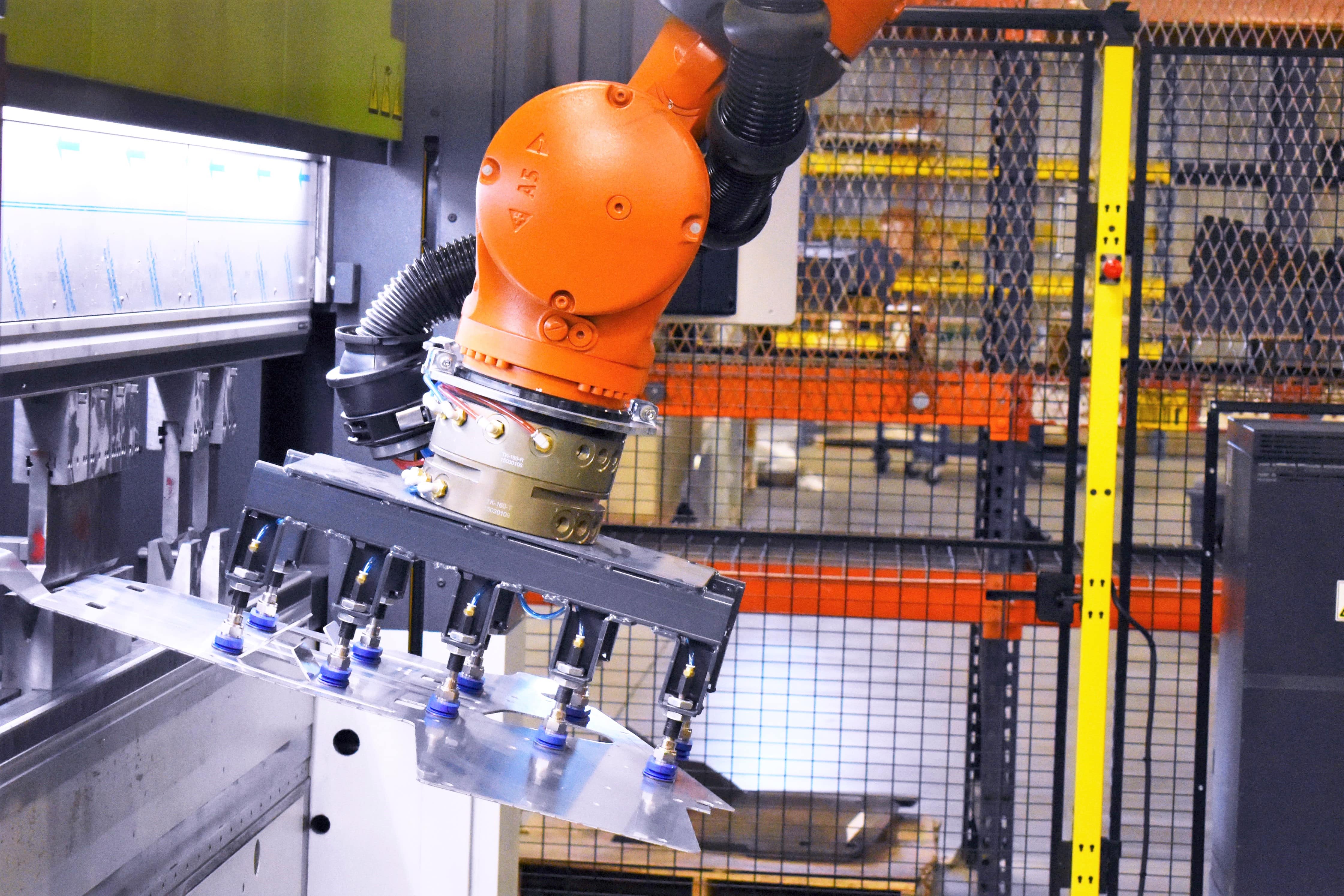

Put Manufacturing Technology to Work

Part of the reason behind this North American manufacturing renaissance is the adoption of state-of-the-art technology. Capabilities like sheet metal fabrication, precision machining, and plastic injection molding all require increasingly intelligent machines and equipment. Modern technologies provide better efficiency and productivity, which is better for a company’s bottom line. Cadrex has state-of-the-art business intelligence, automation, and robotics to maximize its productivity across the company.

A report from The Manufacturing Institute indicates more advanced processes and innovations require workers to have enhanced technological and data analysis skills. Manufacturers need employees who can interact with technology and solve problems, who bring critical thinking and creativity to the factory floor. As manufacturing technology advances, companies encourage continuous learning for their workers… enhancing career opportunities while establishing a positive return on investment.

How to Select a North American Manufacturing Partner

There are numerous benefits to partnering with a North American manufacturer. When searching for a contract manufacturer, it’s best to look for a company that has rich experience, is devoted to the communities it serves, and takes quality seriously.

Operating out of the U.S. and Mexico allows Cadrex to provide beneficial services to customers that simply wouldn’t be possible in overseas manufacturing operations. We have unmatched resources in North America to quickly deliver custom mechanical solutions at scale. Our broad capabilities at our collaborative sites allow us to design, create, and develop highly complex parts and mechanical assemblies. Cadrex uses state-of-the-art tools, automation, and business intelligence to enhance our partnerships with innovative North American companies.

Tap into our technical expertise and breadth of capabilities. Contact Cadrex to find out how our solutions can help your company build a better product.

Recent Insights

News

Blog

White Papers